Bespoke and Catalogue Components for Scientific Instrument Manufacturers

Designed to be at the heart of your supply chain

VACGEN are a trusted supply chain partner for organisations who require a steady supply of UHV components and sample manipulators. We support equipment manufacturers around the world with high quality components to ensure their supply chain is always moving. Components can adhere to strict test procedures set out by the OEM.

XYZ Precision Sample Manipulation

Precision movement, stability and positioning of samples and substrates within a vacuum envelope is an essential process in material analysis. Vacgen's class 7 cleanroom is equipt with flow-lines and test facilities to ensure quality is paramount and manipulators are built to the same standard every time. Options include heating and Ln2 cooling modules for 18mm flag style transfer and larger samples.

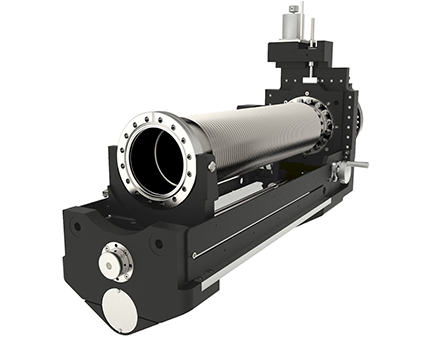

Drives and Motion Components

Sample transfer is an integral part of every system, being able to successfully translate a sample from the load lock to the analysis or deposition chamber. Vacgen have a wealth of knowledge when it comes to movement in vacuum and offer an array of standard drives and motion. If you are looking for a magnetically coupled transfer device with long travel lengths, zero outgassing and high bake-out temperatures, then check out the MLRV series.

Ultra-High Vacuum Valves

UHV Valves are an integral part of every system build. We supply a comprehensive range of valves, from all metal right angle valves for true UHV applications to ultra-fine controllable leak valves which have been designed to eliminate hysteresis. Our aim is to provide you with the very best UHV valves. These can be manufactured in large batch sizes with optional pre-bake and RGA services for OEM customers.

Bespoke Auxiliary Components

Bespoke flanges, viewports or consumables can be manufactured in large batch sizes to accommodate your supply chain. Customers will need to supply a drawing and yearly forecast for Vacgen to understand capacity and keep ahead of your demand. Other auxiliary products such as fittings, viewports and gaskets can be added to your forecasted demands.

Why Choose VACGEN as your supply partner?

With over 50 years industry experience, our core competence is in the expert design, engineering, manufacture and clean-room assembly of chambers and manipulation subsystems, offering a wide portfolio of high and ultra-high vacuum chambers for multiple applications in the vacuum industry. From the manufacture of the first UHV valve to some of the most advanced vacuum research systems built, our long spanning history has given us an incredible grounding in the needs of our customers and how we can support new projects through the design phase, product delivery and installation, and ongoing support.

Trusted

We are a trusted supplier of vacuum companies big and small and would love to be at the heart of your supply chain.

State of the art production line

Our production facility is a purpose built state-of-the-art building, designed around machining centres and flow lines for volume production capacity.

Everything under one roof

From 5-axis complex geometrical chambers with post-welding operations to ultra high vacuum cleaning techniques, we have everything under one roof.

Experts in UHV

Ultra-high vacuum product design and manufacture has been a central part of our business for over 50 years and we have the skills and knowledge to undertake your UHV project.