Electromechanical Assemblies

VACGEN are your electromechanical assembly experts, building to your design within our class 7 clean room - with the added advantage of our in-depth knowledge of vacuum.

Typical electromechanical assemblies could include lens assemblies, heater stages or manipulation sub-assemblies – but whatever you need, no matter how bespoke, you can trust our team to deliver a solution to suit your exact application.

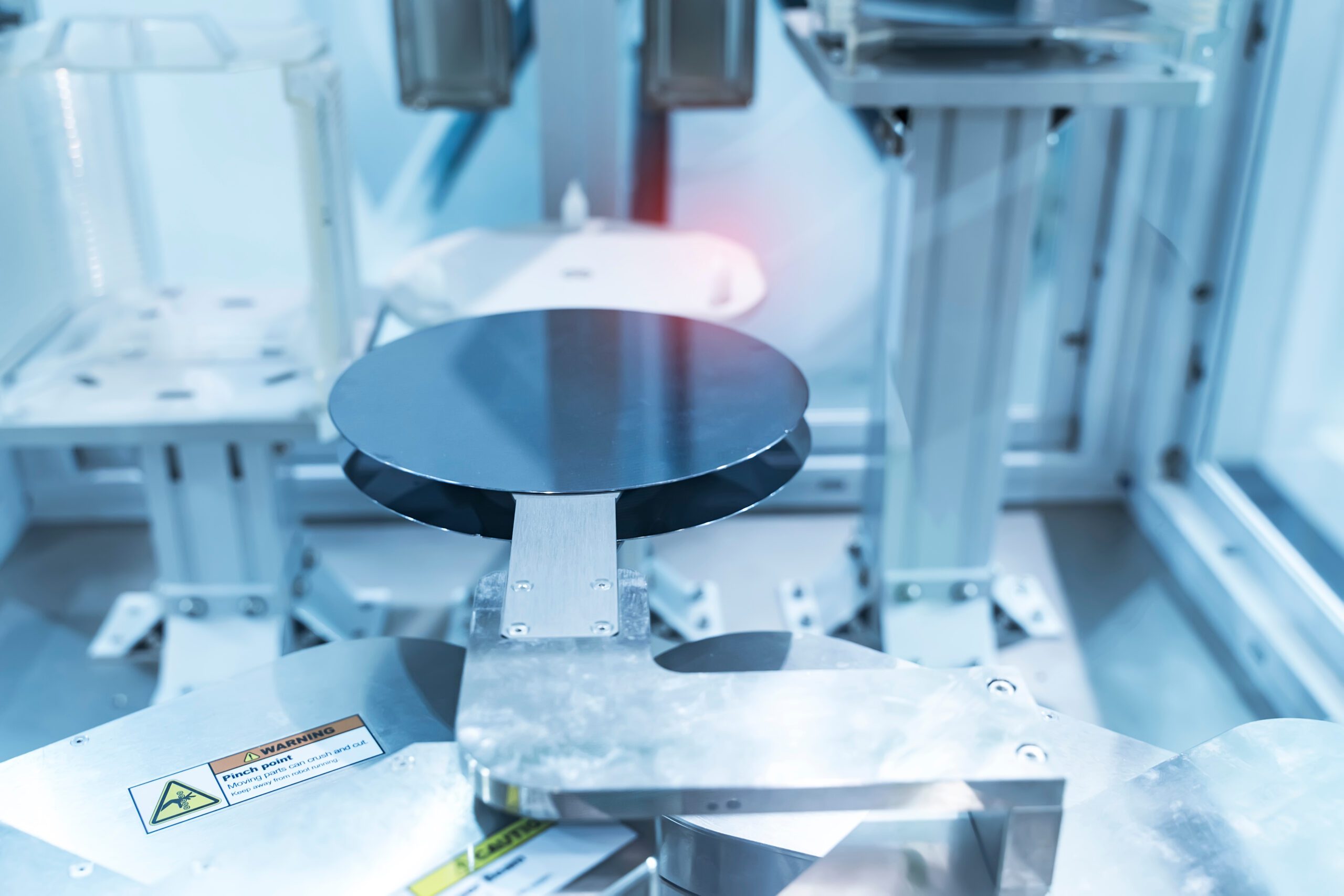

From the semiconductor industry to material science, mass spectrometry and material deposition, VACGEN are the experts you need to support innovative engineering projects that guarantee success during application.

BUILT IN ISO CERTIFIED CLEANROOM

Our Project Process, Built for Your Success

Within any vacuum chamber, there is a need for high-tech electromechanical assemblies that are reliably built and contaminant-free.

For a scalable and cost-effective solution, electromechanical products assembled by VACGEN are built in a Class 7 Cleanroom, as part of a manufacturing flow line in our state-of-the-art production facility. The whole process is centred around providing exceptional value for OEMs, with quality ingrained.

Assemblies Built to Print

At VACGEN, our innovative manufacturing flow lines provide a scalable approach to manufacturing production – especially when it comes to volume, Copy Exact assemblies.

We are proud to work to high Copy Exact standards in the manufacture of our vacuum solutions, reducing the time and money required to re-engineer the same products and process. Using this method, we can produce identical high-quality products, time and time again.

Comprehensive Test Procedures

We enable even the most unique product requirements to be safely met – this includes comprehensive test procedures to guarantee the accuracy of our production methods.

Depending on your requirements, we can include Residual Gas Analysis on assemblies before shipping from our facility, giving you ultimate peace of mind.

Cleanroom-Ready Manufacturing

Our state-of-the-art facility is set up for volume production, allowing us to keep up with your demands and scale up or down, precisely as required.

Before production begins, we can produce rapid prototypes to confirm your material selection and further guarantee that the design is compatible with your overall system build. In addition, our assemblies are built to print and can include comprehensive test procedures – as well as one-off batches to assess.