Introduction

Vacuum manipulation plays a critical role in surface science and material deposition applications. If you're new to the world of vacuum manipulation, the numerous terms and components can seem daunting. Vacgen is here to explain these terms and introduce some essential tools and equipment we have on offer.

Fundamentals of Manipulation

Let's start by understanding the basics. A vacuum system typically includes a load lock chamber, process chamber, sample preparation and transfer setup, analysis tools, pressure controls and a manipulator. The manipulator may include modules, such as the Z stage, XY stage, rotary drive, and sample holder. These are designed to work in harmony, providing flexible, yet highly complex sample movements.

Z Plane

The Z stage allows for movement in the Z axis, while the XY stage facilitates movement along the X and Y axes. The use of bolt hole orientation and universal flanges ensures that the manipulator can be fitted onto any chamber, regardless of its bolting pattern; deviation at this stage can lead to an off-kilter rotation point, bad news in the precise world of micro measurement!

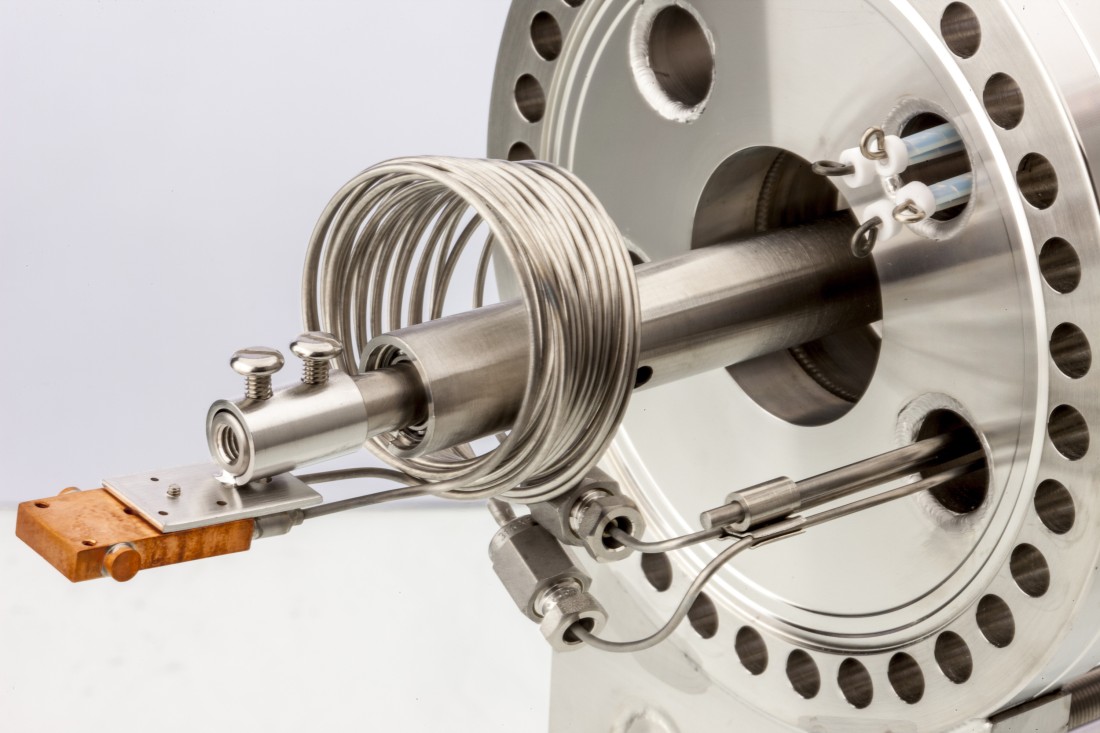

Bellows

An important part of any manipulator setup is the bellows. Vacgen offers both single and dual bellows. Single bellows are less rigid and support a smaller probe size, while dual bellows offer enhanced rigidity and support larger probe sizes, like the Omniax model which accommodates a 50mm probe. Rotation, an essential component of vacuum manipulation, involves primary (R1), secondary (R2), and tertiary (tilt R3) rotations. Vacgen offers primary and secondary rotation operation via rotary drives like the ZRD1 and ZRD2. The ZRD1 is state-of the art for primary rotation, whereas the ZRD2 controls both primary and secondary rotation.

Alternatives

There are other methods for primary rotation: Differentially Pumped Rotary Feedthroughs (DPRFs) and RP100 which benefit from being hollow. DPRFs are particularly effective when rotating a cryostat or cold finger about an axis. Meanwhile, the RP100 is a dedicated rotary platform designed to fit the Wide Bore Omniax; the RP100mm has a 100mm clear bore and is ideal for rotating wider probes.

Sample Holders

Next are the sample holders which hold the actual samples themselves. Sample holders can be moved in primary rotation (R1), secondary rotation (R2), and tilt or flip (R3). Some sample holders from Vacgen include SH1 (R1 only), SH2 (R1 and R2), and SH2RT (R1 and R3). Substrate transfer options also form part of the manipulation process to allow seamless movement of the sample around the vacuum system. Vacgen offers various substrate and transfer options such as 18mm Flag EBH Heater Assembly, 18mm Flag PBN Heater Assembly, and standard 14mm HST Assembly.

Feedthroughs and Thermocouples

Feedthroughs and thermocouples are essential for carrying power to the sample heater and allowing temperature measurement. Vacgen's feedthroughs adhere to EU low voltage regulations and come in either N or K type thermocouple connections. Cooling of the sample is achieved using Liquid Nitrogen (LN2), and sample bias and electrostatic shield are used for voltage application and protection of ceramics.

To facilitate ease of operation, Vacgen offers motorisation options with the SIM STEP controller, a stepper motor controller compatible with any manipulator. It can be controlled via a Jog Box or an RS232/USB connection.

In Summary

It may seem like a lot to take in, but we hope we’ve explained some of the hardware and its processes in Vacgen’s manipulation range. Our products include a range of manipulators like the Miniax, HPT, Transax, Omniax, and Omniax Wide Bore. These manipulators differ in Z travel length, XY travel, construction, clear bore, stability, and of course, application. Vacgen has a range of tools and components designed to offer great flexibility for vacuum manipulation. Whether it's for surface science or material deposition, Vacgen offers an array of equipment to meet your vacuum manipulation needs. Call our experts today for help and advice on your next project.