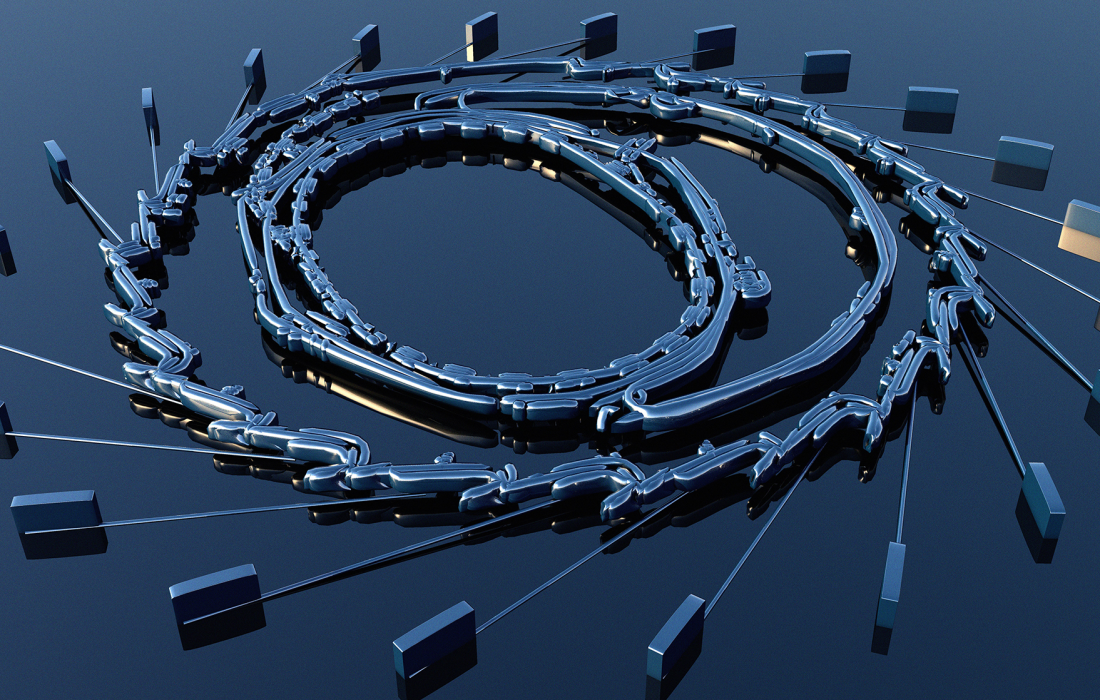

Synchrotron light sources are among the most advanced tools for scientific research, producing high-intensity, tunable beams of X-rays, infrared, and ultraviolet light.

These beams are crucial for exploring materials at the atomic level, enabling breakthroughs in fields like medicine, nanotechnology, and environmental science. However, the quality and performance of these complex facilities hinge on one critical factor: precision engineering. Specifically, ultra-high vacuum (UHV) components, such as beamline chambers, mirror mounts, and precision seals, play an essential role in optimising the performance and ensuring that synchrotron light sources deliver the desired quality and stability. In this blog post, we’ll explore how precision-engineered UHV components enhance synchrotron light sources and why investing in high-quality components is vital for maximising output.

The Importance of UHV in Synchrotron Light Sources

Synchrotron light sources operate in extremely controlled environments, where vacuum conditions are critical to maintaining the integrity of the light beams. In synchrotrons, ultra-high vacuum (UHV) conditions, which measure pressures lower than 10^−9 mbar, are essential to prevent contaminants, particles, or gases from interacting with the beam. Even the smallest contamination can lead to energy loss, scattering, or noise in the data, reducing the accuracy of experiments.

Precision engineering ensures that UHV components function optimally under these extreme conditions. This includes maintaining perfect alignment and mechanical stability of the system's components, which are subjected to constant thermal cycling, high pressures, and magnetic fields.

Key Precision-Engineered UHV Components

Beamline chambers are the central vessels through which synchrotron light travels. Precision-engineered beamline chambers are designed to maintain the exact vacuum levels required for beam propagation. These chambers are made from materials such as stainless steel or aluminium, chosen for their low outgassing rates and resistance to high-energy radiation.

Impact on Quality: Well-engineered beamline chambers minimise the chance of residual gases entering the beam path, reducing the likelihood of collisions with photons and maximizing the intensity and purity of the light. Their precise geometries also ensure minimal beamline obstruction, preserving the beam’s coherence and energy.

2. Manipulators

UHV sample manipulators are key components that enable precise positioning and handling of the samples under investigation within the ultra-high vacuum environment of a synchrotron.

Impact on Quality: Precision-engineered UHV sample manipulators allow researchers to move, rotate, tilt, and cool or heat samples with sub-micron precision. This level of control is critical for ensuring that the synchrotron beam hits the exact part of the sample required for analysis, optimising the interaction between the beam and the material under investigation. High-quality manipulators also minimise vibrations or mechanical drift, ensuring that the samples remain stable throughout the entire experimental process, improving the accuracy of the measurements and data collected.

In synchrotron systems, mirrors are used to direct, focus, and fine-tune the beams. The quality of these mirrors is directly related to their mounts, which must hold them in a stable, precise position.

Impact on Quality: Precision rotary drives are engineered to sub-micrometer tolerances, ensuring that the attached mirrors remain perfectly aligned in the specific angle needed even as they undergo thermal or mechanical stresses. This level of precision reduces aberrations and deviations in the beam path, preserving the beam’s brilliance and focus. High-quality rotary drives also enable quicker alignment, reducing downtime and improving operational efficiency.

Maintaining an ultra-high vacuum environment requires flawless sealing at the interfaces between different UHV components. Any leakage can lead to loss of vacuum, causing contamination and significantly degrading the synchrotron’s performance.

Impact on Quality: Precision-engineered auxiliary products, such as metal gaskets or elastomer O-rings, are designed to withstand extreme conditions and prevent even the slightest leakage. These seals must also accommodate thermal expansion and contraction without losing integrity. High-quality precision seals reduce maintenance downtime and ensure the synchrotron can operate continuously at peak efficiency.

How Precision Engineering Improves Synchrotron Output

1. Minimised Downstime

Precision-engineered UHV components are built for durability and long-term stability, reducing the need for frequent maintenance or recalibration. This translates into reduced operational downtime, allowing more experiments to be conducted and improving the overall output of the facility.

2. Increased Beam Stability

The key to high-performance synchrotron light sources is the stability of the beam. Components like rotary drives and beamline chambers, when precision-engineered, ensure the beam remains stable and focused over long periods. This is crucial for experiments that require consistent beam properties, such as those conducted in materials science and structural biology.

3. Enhanced Beam Quality

Any imperfections in UHV components can introduce noise or scatter to the beam, reducing its brilliance and coherence. By using high-precision parts, synchrotrons can produce cleaner, more focused beams, which are critical for high-resolution imaging and analysis.

4. Cost Efficiency

Although precision-engineered components may come at a higher initial cost, their reliability and long lifespan reduce the overall cost of ownership. By minimising the need for frequent repairs and replacements, facilities can save on operational costs in the long run, making it a worthwhile investment.

Summary

The quality of a synchrotron light source is only as good as its weakest component. Ultra-high vacuum environments are unforgiving, and any imprecision can lead to significant performance degradation. By investing in high-quality, precision-engineered components such as beamline chambers, rotary drives, and gaskets, synchrotron facilities can maximise their output, improve beam stability, and enhance the quality of their scientific data.

Get in contact with us today to find out how VACGEN can help you: sales@vacgen.com