At VACGEN we welcomed Nusrat Ghani, MP for Sussex Weald, at our manufacturing facility.

ultra-high vacuum

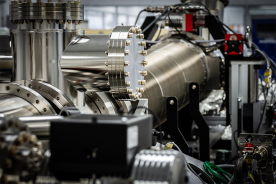

Nuclear fission and nuclear fusion represent two fundamental processes for harnessing atomic energy, both of which rely on specific technologies to manage and sustain reactions. Although their mechanisms and requirements are different, both fission and fusion reactors can benefit from vacuum components in critical areas. Let’s explore how these components are used.

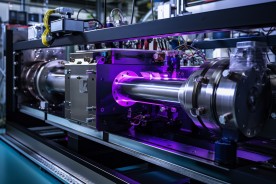

Synchrotron light sources are among the most advanced tools for scientific research, producing high-intensity, tunable beams of X-rays, infrared, and ultraviolet light.

Nuclear clean energy needs vacuum for controlled environments, efficiency in reactions and safety in nuclear fusion and fission technologies.

Extreme high vacuum (XHV) environments are becoming a popular option for a range of applications i.e. Molecular Beam Epitaxy (MBE). Given the extreme situations required for XHV, there are a variety of issues that coincide with this. One persistent issue is the removal of hydrogen gas.

Material analysis is a foundation of scientific research and industrial applications, providing critical insights into the composition, structure, and properties of materials. Among the array of techniques available, Secondary Ion Mass Spectrometry (SIMS) stands out for its exceptional sensitivity and depth profiling capabilities.

- Jan 22 2024

New Year, New Machinery

Categories: Factory NewsIntroduction

We are delighted to announce the acquisition of two advanced CNC machines from DMG Mori. These state-of-the-art machines represent a significant investment in our commitment to delivering unparalleled precision, repeatability, and efficiency in our production processes.

- Categories: Factory News

Introduction

A Coordinate-Measuring Machine (CMM) is a device used in manufacturing and quality control to measure the physical geometrical characteristics of an object. It is commonly used in industries such as aerospace, automotive, and precision engineering. By using a coordinate measuring machine (CMM), VACGEN can guarantee precision, paramount in the modern and fast-changing manufacturing industry. Learn more about the CMM and they’re potential in the industry below.

Introduction

The photomask is a critical part of the semiconductor fabrication process and inspection processes often involve sophisticated electromechanical assemblies to achieve high precision and reliability. Some of the key electromechanical assemblies commonly used in reticle inspection systems are XYZ stages, robotic arms, inspection and alignment equipment. In this blog we’ll take a look at various semiconductor inspection tools and their uses in the wafer inspection process.

Introduction

Metrology plays a crucial role in the semiconductor industry by providing measurement and inspection solutions to ensure the quality, accuracy, and reliability of semiconductor devices. Various metrology equipment is utilised throughout the semiconductor manufacturing process, with many of the processes requiring a vacuum environment to perform affectively.