Material analysis is a foundation of scientific research and industrial applications, providing critical insights into the composition, structure, and properties of materials. Among the array of techniques available, Secondary Ion Mass Spectrometry (SIMS) stands out for its exceptional sensitivity and depth profiling capabilities.

When combined with vacuum conditions SIMS can offer unparalleled precision and clarity. This blog investigates the principles, advantages, and applications of Secondary Ion Mass Spectrometry (SIMS) in material analysis enhanced by vacuum conditions.

Understanding Secondary Ion Mass Spectrometry (SIMS)

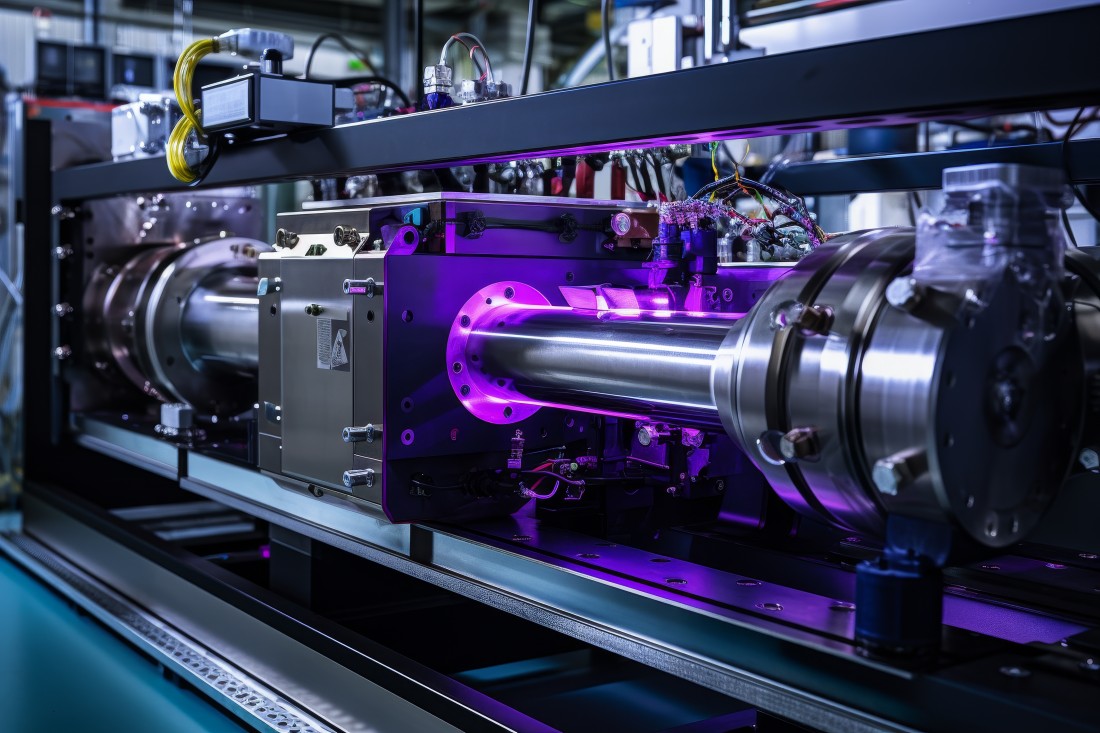

SIMS is an analytical technique used to characterise the composition of solid surfaces and thin films. The process involves bombarding a sample with a focused primary ion beam, which sputters secondary ions from the surface. These secondary ions are then analysed using a mass spectrometer to determine their mass-to-charge ratio, revealing the elemental, isotopic, or molecular composition of the sample.

The Role of Vacuum in SIMS

Conducting SIMS under vacuum conditions significantly enhances the performance of the technique. It can reduce the presence of contaminants and residual gases that could interfere with the ionisation process. It improves the sensitivity of the analysis by minimising the scattering of secondary ions allowing for more ions to reach the detector. Improving the sensitivity by enabling the detection of trace elements and isotopes. Vacuum conditions allow for enhanced depth profiling and extended mass range so heavier ions that would otherwise be difficult to detect can be analysed.

Types of SIMS advanced by Vacuum

There are several variations of SIMS that benefit from vacuum enhancement. For example, Dynamic SIMS, Static SIMS and Time-of-Flight SIMS (ToF-SIMS). The vacuum environment ensures high resolution and sensitivity, critical for detailed surface and depth analysis.

To ensure that a system can benefit from vacuum technology, a variety of vacuum solutions are required.

Chambers

Vacuum Chambers are vital to effectively analyse materials during SIMS. The chambers are designed specifically to fit each purpose within a vacuum system.

Primary Analysis Chamber: Stainless steel chamber designed to includes ports for the ion source, sample stages, secondary ion detectors, and various diagnostic tools. The geometry of the chamber is optimised to minimise dead volumes and enhance vacuum performance.

Load-Lock Chamber: Load-lock chambers allows samples to be introduced and removed without breaking the vacuum in the main analysis chamber. Load-lock chambers are equipped with their own pumping systems and are connected to the main chamber via valves. They often include a sample transfer mechanism to move samples into the main chamber.

Preparation Chamber: Preparation chambers are used for sample cleaning, coating, or other preparatory steps before analysis. These chambers maintain vacuum conditions to prevent contamination during sample preparation. This chamber is linked to the main chamber through valves, allowing samples to be transferred without exposure to atmospheric conditions.

After the design process has been completed, VACGEN can offer an option to pre-bake and RGA scan; this will reduce the presence of contaminants and residual gases that could interfere with the ionisation process.

Valves

Valves are vital so that samples and equipment can move between chambers without leaking from the vacuum system. Valves are specifically designed to meet the requirements of a vacuum system. Some of the types of valves required in SIMS are:

Gate Valves: Gate Valves are used to isolate different sections of the vacuum system, such as between the load-lock chamber and the main analysis chamber. They are designed to provide a vacuum-tight seal and they are able to operate without introducing contamination or significant pressure changes.

Right-Angle Valves Right-Angle Valves are typically employed in vacuum lines where a right-angle flow path is required. They provide precise control over gas flow and isolation.

Sample Manipulators

A multi-axes manipulator is used to position a sample within the vacuum chamber. Combining a manipulator with a sample holder and rotary drive allows precise positioning. They often include capabilities for heating, cooling, and rotating the sample to ensure comprehensive analysis. As well as the option to be fully motorised to ensure precision.

Auxiliary Products

UHV Accessory products are vital to ensure the smooth working of a vacuum system. Specifically for SIMS you will need:

Vacuum Gaugessuch as, Pirani gauges for rough vacuum measurements and ion gauges for UHV conditions. These gauges are essential for monitoring and controlling the vacuum levels within different sections of the SIMS system.

Residual Gas Analysers (RGA) monitor the composition of gases in the vacuum system to detect contamination or leaks. RGAs are critical for maintaining the purity of the vacuum environment.

Summary

Secondary Ion Mass Spectrometry (SIMS) represents a significant advancement in material analysis, offering unmatched sensitivity, precision, and depth profiling capabilities. By leveraging vacuum conditions, SIMS eliminates atmospheric interference, enhances signal quality, and extends the range of detectable ions. This makes it an indispensable tool for researchers and industries seeking detailed and accurate compositional analysis.

As technology advances, SIMS will continue to evolve, opening new frontiers in material science and related disciplines. The ability to analyse materials with such high precision and sensitivity will undoubtedly lead to breakthroughs in our understanding and utilisation of materials, driving innovation and progress across various fields.Contact us today to start your journey.