At VACGEN we welcomed Nusrat Ghani, MP for Sussex Weald, at our manufacturing facility.

Vacuum Technology

Nuclear fission and nuclear fusion represent two fundamental processes for harnessing atomic energy, both of which rely on specific technologies to manage and sustain reactions. Although their mechanisms and requirements are different, both fission and fusion reactors can benefit from vacuum components in critical areas. Let’s explore how these components are used.

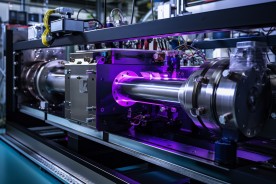

Synchrotron light sources are among the most advanced tools for scientific research, producing high-intensity, tunable beams of X-rays, infrared, and ultraviolet light.

Nuclear clean energy needs vacuum for controlled environments, efficiency in reactions and safety in nuclear fusion and fission technologies.

Extreme high vacuum (XHV) environments are becoming a popular option for a range of applications i.e. Molecular Beam Epitaxy (MBE). Given the extreme situations required for XHV, there are a variety of issues that coincide with this. One persistent issue is the removal of hydrogen gas.

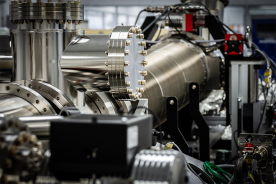

Material analysis is a foundation of scientific research and industrial applications, providing critical insights into the composition, structure, and properties of materials. Among the array of techniques available, Secondary Ion Mass Spectrometry (SIMS) stands out for its exceptional sensitivity and depth profiling capabilities.

Synchrotron science shines across disciplines, illuminating a pathway for scientific discoveries. Synchrotrons use synchrotron radiation, which is produced when charged particles, typically electrons, are accelerated to nearly the speed of light in a circular or spiral path by strong magnetic fields. This process generates intense beams of light that cover a broad spectrum, from infrared to X-rays.

In case you haven’t heard already, VACGEN are going green. We’ve installed 609 solar panels on our UK headquarters roof and are soon to be installing EV charging points too.

Introduction

Material deposition refers to the process of adding or depositing material onto a substrate or surface. This can be achieved through various techniques and methods, each suited to different applications. For many of these applications, vacuum is an essential requirement to achieve the required quality.

Introduction

The photomask is a critical part of the semiconductor fabrication process and inspection processes often involve sophisticated electromechanical assemblies to achieve high precision and reliability. Some of the key electromechanical assemblies commonly used in reticle inspection systems are XYZ stages, robotic arms, inspection and alignment equipment. In this blog we’ll take a look at various semiconductor inspection tools and their uses in the wafer inspection process.