Extreme high vacuum (XHV) environments are becoming a popular option for a range of applications i.e. Molecular Beam Epitaxy (MBE). Given the extreme situations required for XHV, there are a variety of issues that coincide with this. One persistent issue is the removal of hydrogen gas.

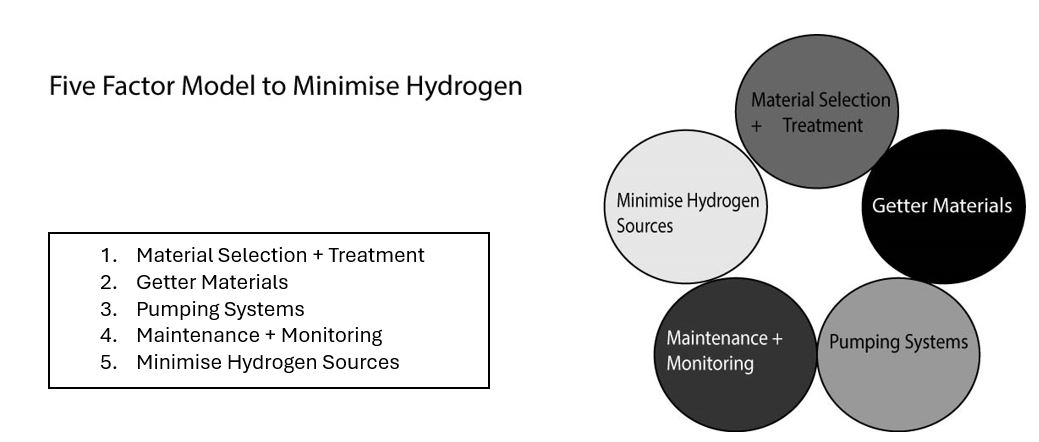

This blog post proposes a 5-factor model that can be used to reduce the presence of Hydrogen in your vacuum system.

What is an XHV Environment?

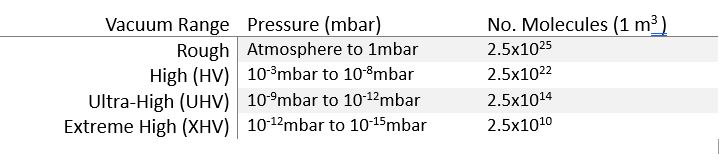

An extreme high vacuum environment refers to an environment with very low pressure. To put this into perspective, the table below shows the Pressure and the Number of Molecules in a chamber from a rough vacuum range to extreme vacuum range. .

Understanding Hydrogen in XHV Environments

Hydrogen; It’s small atomic size and high diffusion rate makes this element incredibly difficult to reduce in XHV Environments. But, where does it originate from? Hydrogen is outgassed from materials used in vacuum chambers. Hydrogen can also enter the vacuum chambers through leaks. Lastly, water vapor, which often outgasses from

What’s the plan with the Hydrogen?

In order to prevent the abundance of this element a 5-factor model can be used to determine an effective plan of action.

1. Material Selection and Treatment

Choosing appropriate materials and treating them properly can significantly reduce hydrogen outgassing. For instance, low-carbon stainless steel (316L) has a lower hydrogen solubility compared to alternative materials. Coating this Stainless Steel with a coating such as, titanium nitride (TiN) or amorphous carbon, can act as barriers to hydrogen diffusion. Then completing an initial bake to high temperatures of 800-900°C in a vacuum environment to remove hydrogen and other gases. Adding other components that could be sensitive to baking the chamber into the system then repeat baking the Vacuum Chamber at elevated temperatures (120-200°C). This accelerates the desorption of water and other gases from surfaces, significantly reducing the hydrogen load.

2. Getter Materials

Getters are materials that absorb and trap gases. This is very beneficial in order to maintain XHV. Getter materials can be specialised for Hydrogen removal in XHV conditions. For example, a Titanium Sublimination Pump (TSP) can release titanium vapor in order to form a film that can capture Hydrogen particles within a vacuum environment.

3. Pumping Systems

Using an appropriate combination and placement of pumps is crucial for maintenance of XHV: NEG Pumps: These pumps absorb hydrogen and other gases onto chambers surface, providing a high capacity for hydrogen. Ion Pumps: Effective at pumping hydrogen due to their high pumping speed for light gases. Cryopumps: Can capture hydrogen by freezing it onto cold surfaces.

4. Regular Maintenance and Monitoring

Regularly monitor the vacuum system for leaks and outgassing. Employ residual gas analysers (RGA) to identify and quantify the presence of hydrogen and other gases. Scheduled maintenance should include:

- The use of leak detectors can help to identify any leaks in the system. If a leak is noticed be sure to contact your vacuum supplier as soon as possible to prevent downtime.

- Pump Maintenance: Regularly service ion pumps, cryopumps, and TSPs to ensure optimal performance.

5. Minimise Hydrogen Sources

Take steps to minimise hydrogen outgassing sources within the chamber. Minimising the use of materials and substances that release hydrogen, such as certain polymers and lubricants can greatly help to reduce outgassing. Whilst maintaining controlled environments around the vacuum chamber to reduce the ingress of hydrogen from external sources.

Summary

Achieving and maintaining an XHV environment free of hydrogen is challenging but feasible with the right strategies. Material selection, chamber preparation, effective pumping, and regular maintenance are key to minimising hydrogen backgrounds. By implementing these practices, researchers can ensure the integrity and performance of their MBE systems and Synchrotron experiments. For more detailed guidance tailored to your specific setup, consulting with vacuum technology experts (VACGEN). Keeping up to date with advancements in vacuum technology can also provide new tools and techniques for managing hydrogen in XHV environments.