There are countless vacuum chamber builds available and, if you partner with VACGEN, you can benefit from a bespoke project that’s tailored to your exact needs – no matter how advanced the application. We’re the experts in ultra-high and extreme vacuum chamber manufacturing; but what’s the difference, exactly?

Let us explain…

High Vacuum Chambers

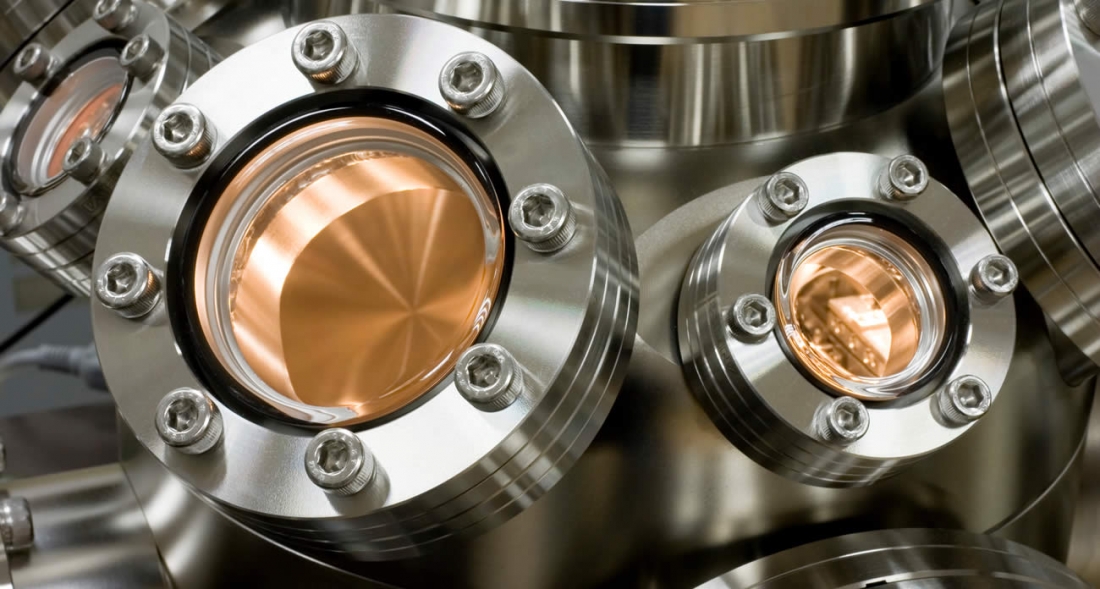

A typical high vacuum chamber will be built using high vacuum flanges (Klein Fittings). When vacuum chambers, tubing and vacuum pumps are joined to each other, you’ll find Klein flange at the end of each connecting tube.

The ISO standard of quick-release flange is often called a Quick Flange (QF) or Klein Flange (KF). It generally takes the form of an O-ring to seal and clamp arrangement.

High vacuum O-rings are frequently made of a synthetic, fluorinated hydrocarbon (fluorocarbon) rubber. It’s a good option for some applications involving oils, fuels, and mineral acids, but it can’t be baked at high temperatures - so it’s impossible to remove every trace of moisture from surfaces, the seals would also be permeable.

For this reason, high vacuum chambers aren’t suitable for highly complex applications that require exceptionally clean environments or or ultra high vacuum environments.

Ultra-High Vacuum Chambers

Ultra-high vacuum technology is essential for academic research, or advanced semiconductor applications, which can only accept the most enhanced levels of vacuum and cleanliness.

To achieve ultra-high vacuum, you need to “routinely” bake the environment at over 100 °C. Of course, this means you need to have metal seals on the flanges which can withstand these temperatures through many cycles.

At VACGEN, we can offer a pre-bake of the chamber with an RGA (Residual Gas Analysis) scan. This will:

- Prove the integrity of the vacuum chamber at elevated temperatures

- Show the chamber is cleaning up through the bake, as demonstrated by the reduction of hydrocarbons seen on the scan once the baking process is complete.

This will empower you to guarantee and demonstrate that the right requirements are being met at every stage of your process.

Extreme High Vacuum Chambers

Extreme high vacuum chambers reach even lower pressures than their ultra-high vacuum counterparts (as low as 10-12 mbar, compared to 10-10 mbar for UHV). They are often the vacuum chamber of choice for extremely advanced sectors such as synchrotron science.

The ultimate pressure in the chamber is defined by the 1) total outgassing rate from all the surfaces and 2) the effective pumping speed.

Outgassing

To get lower than ultra-high vacuum pressures, you need to reduce the outgassing.

Hydrogen (H₂) is embedded into the bulk of the material in stainless-steel chambers. Outgassing of the H₂ could occur when the stainless-steel is exposed to a vacuum; this would eventually cause it to condense on other materials, depleting the chamber’s ultra-clean benefits.

There are two ways to reduce the outgassing:

- Vacuum firing. By immersing the whole chamber inside a vacuum furnace at 950/1000°C for two-to-four hours, the majority of H₂ will be expelled Because the H₂ came from the bulk during the forming of the steel, it will not reabsorb once it comes back into the atmosphere.

- Air baking. This will help passivate the surface of the chamber (i.e., trap the H₂ into it). It raises a very thick oxide layer to act as a block for the H₂ escaping.

Effective Pumping Speed

The ultimate pressure in the vacuum chamber is also defined by effective pumping speed.

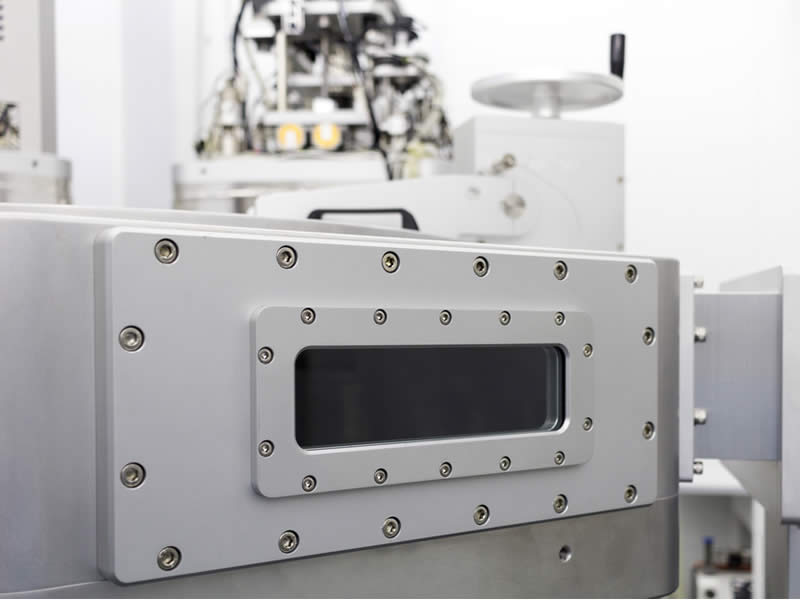

MBE-style chambers are wide open, with no conductance limitations - so they should be easy to pump. You can accommodate large pumps on large openings.

Synchrotron chambers, however, are becoming increasingly narrow with longer sections – so the effective pumping becomes harder.

How To Improve Pumping Speed For Extreme High Vacuum

The first way to improve pumping speed is to use a chamber design with little in the way of conductance limits. As this isn’t possible on synchrotron chambers, you need to consider other options – NEG getter pumps or NEG coatings to supplement smaller traditional pumps such as turbo’s and ion pumps.

NEG Getter Pumps

NEG getter pumps are vacuum pumps with a working principle based on chemisorption and absorption. They produce ultra-high vacuum without moving parts or valves, making them highly effective, quiet, and low maintenance.

NEG pumps have several unique characteristics which make them particularly appealing when moving from ultra-high vacuum to extreme high vacuum.

For example, they are:

- Amagnetic

- Radiation compatible

- Operational without power.

NEG Coatings

There are typically three elements to an NEG coating (Titanium, Zirconium, and Vanadium)- but you can also consider a fourth to reduce the actuation temperature (Hafnium). These are usually magnetron sputtered.

As a result of using this coating, the surface of the vacuum chamber - normally an outgassing source - becomes a vacuum pump.

Other benefits include:

- High and uniform pumping speed inside narrow chambers

- Simpler design of the vacuum chamber (for example, no need for pumping antechambers and less external ports).

No matter how unique the requirement, we can provide the end-to-end solution that furthers the capability of your process – including getting to ultra-high and extreme high vacuum.

If you need vacuum technology to support your manufacturing, testing or research environment, VACGEN are here to help. We create advanced vacuum solutions for even the most complex applications.

Do you have a project that you’d like to discuss? Our expert team is ready to help. Get in touch today