A brief history on the origins of Copy Exactly!

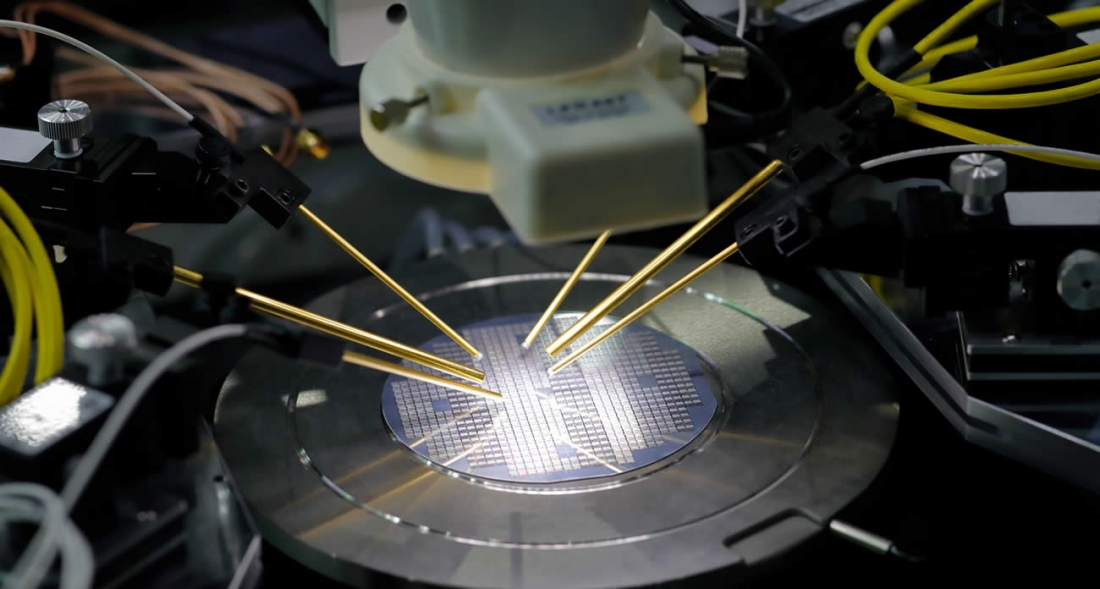

The 'Copy Exact' (otherwise known as ‘Copy Exactly’, ‘Copy Exactly!) methodology was pioneered by Intel Corporation in the 1980s to enable semiconductor manufacturers to ramp up production of microchips quickly, control quality and to guarantee identical results across multiple production facilities. The process and principles of Copy Exactly have since been heavily adopted by the wider electronics industry due to the range of benefits it offers to companies and customers alike.

The foundations of Copy Exact Manufacturing

Although there is no centrally recognised industry standard (such as ISO) set for Copy Exact certification, there are some key principles and attributes which are core to the overall process.

- Training. Personnel are required to be trained and qualified so that they meet the standards of the relevant copy exact process. Typically, it is the responsibility of the primary or direct equipment manufacturer to ensure that all their sub-tier suppliers are trained to comply with their own Copy Exact standards.

- Documentation. An essential part of copy exactly manufacturing process. Manufacturers need to have extensive documentation that details every step of the production process. This documentation helps to ensure that each product is made according to the same specifications.

- Validation. The validation of components, materials, design, and manufacturing process is vital to ensure that no changes will be made to any part of the product production.

- Accuracy and precision. Recreating a product down to the smallest detail requires extreme levels of precision. If any part of the process or build changes, this can have disastrous consequences further down the supply chain.

- Repeatability. To get the same product results, each step in the manufacturing process must be repeated identically, every time it is carried out.

- Scalability. The Copy Exact process enables manufacturers to produce more of the same product without compromising the quality.

- Traceability. A critical part of Copy Exact manufacturing is being able to trace back every part of the recorded production process to prove that manufacturers have recreated an identical product to the one that was originally made.

VACGEN’s Copy Exactly! Manufacturing ethos

At VACGEN, we are proud to work to high Copy Exact standards in the manufacture of our market leading vacuum solutions, and truly understand the value and benefits that adhering to such stringent standards brings to both our customers and our organisation.

What are some of the Benefits of using the Copy Exactly! model?

- As well as form and function, the Copy Exact process ensures that aesthetics, material composition and other factors such as quality of the welding all remain consistent with every single product, no matter where it is manufactured.

- Increased product availability due to scaling up production.

- Customers are satisfied with their products and can trust that the Copy Exact process ensures the same standard of product performance on future orders.

- Reduced time and money investing in re-engineering the same products and process.

- Increased product quality is achieved via Copy Exact manufacturing as manufacturers can produce identical high-quality products, time and time again.

- Supply chain trust and continuity is enhanced when all vendors comply to the same set of standards.

Finding a Copy Exact Manufacturing Partner

If you are searching for a certified Copy Exact manufacturing partner for your vacuum chamber project, VACGEN are the ideal partner to support you. We have over 25 years’ experience in the design and manufacture of high vacuum solutions for some of the most advanced sectors in the world, including: semiconductor, research, aerospace & defence, medical and energy.