Semiconductor Industry

Introduction

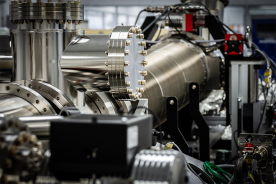

Material deposition refers to the process of adding or depositing material onto a substrate or surface. This can be achieved through various techniques and methods, each suited to different applications. For many of these applications, vacuum is an essential requirement to achieve the required quality.

Introduction

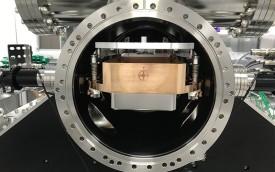

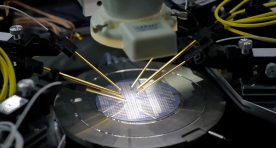

The photomask is a critical part of the semiconductor fabrication process and inspection processes often involve sophisticated electromechanical assemblies to achieve high precision and reliability. Some of the key electromechanical assemblies commonly used in reticle inspection systems are XYZ stages, robotic arms, inspection and alignment equipment. In this blog we’ll take a look at various semiconductor inspection tools and their uses in the wafer inspection process.

Introduction

Metrology plays a crucial role in the semiconductor industry by providing measurement and inspection solutions to ensure the quality, accuracy, and reliability of semiconductor devices. Various metrology equipment is utilised throughout the semiconductor manufacturing process, with many of the processes requiring a vacuum environment to perform affectively.

Introduction

The semiconductor industry relies heavily on vacuum technology for various processes and applications. Vacuum, in this context, refers to an environment with very low pressure and a near absence of gas molecules. Here are some key ways in which vacuum technology is used in the semiconductor industry:

Abstract:

The semiconductor industry plays a vital role in the manufacturing of electronic devices such as microchips, integrated circuits, transistors, and other electronic components. Semiconductor instruments are critical for the research, development, and production processes within this industry.

The 'Copy Exact' (otherwise known as ‘Copy Exactly’, ‘Copy Exactly!) methodology was pioneered by Intel Corporation in the 1980s to enable semiconductor manufacturers to ramp up production of microchips quickly.

There are countless vacuum chamber builds available and, if you partner with VACGEN, you can benefit from a bespoke project that’s tailored to your exact needs – no matter how advanced the application.