Nuclear fission and nuclear fusion represent two fundamental processes for harnessing atomic energy, both of which rely on specific technologies to manage and sustain reactions. Although their mechanisms and requirements are different, both fission and fusion reactors can benefit from vacuum components in critical areas. Let’s explore how these components are used.

Vacuum Chambers

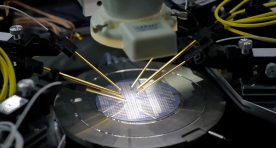

Molecular Beam Epitaxy (MBE) is a highly precise technique for growing thin films, widely used in semiconductor fabrication, nanotechnology, and material science research. One of the most crucial elements of the MBE process is the quality of the vacuum environment in which it takes place.

MBE requires an ultra-high vacuum (UHV) chamber, where the pressure is kept extremely low, typically around 10⁻¹⁰ torr. The ability to maintain such a pristine environment is vital to achieving high-quality film growth and ensuring material purity. In this blog, we’ll explore why vacuum quality is so essential in MBE systems and how it directly impacts the success of the process.

Synchrotron light sources are among the most advanced tools for scientific research, producing high-intensity, tunable beams of X-rays, infrared, and ultraviolet light.

Nuclear clean energy needs vacuum for controlled environments, efficiency in reactions and safety in nuclear fusion and fission technologies.

Extreme high vacuum (XHV) environments are becoming a popular option for a range of applications i.e. Molecular Beam Epitaxy (MBE). Given the extreme situations required for XHV, there are a variety of issues that coincide with this. One persistent issue is the removal of hydrogen gas.

Introduction

A Nickel-Iron Alloy is a type of magnetic shielding material that is often used in electron spectroscopy chambers to minimise external magnetic interference. Electron spectroscopy techniques, such as X-ray photoelectron spectroscopy (XPS) or Auger electron spectroscopy (AES), are highly sensitive to magnetic fields. External magnetic fields can distort the trajectories of electrons, leading to inaccuracies in the measurements and affecting the overall performance of the spectroscopy system.

- Nov 09 2022

Choosing a Vacuum Chamber Manufacturer

Categories: Vacuum ChambersWhether it’s for the semiconductor industry, aerospace engineering or for scientific research purposes, industrial high vacuum system technology is central to many of the key operations that take place.

- Nov 09 2022

How Are Vacuum Chambers Designed?

Categories: Vacuum ChambersAs the central building block in any vacuum system, the design of a vacuum chamber is inextricably linked to the design of the entire system. This which can vary widely, but a vacuum system typically consists of a vacuum pump or pumps, interconnecting piping, viewing window, the central analysis or deposition vacuum chamber...

The 'Copy Exact' (otherwise known as ‘Copy Exactly’, ‘Copy Exactly!) methodology was pioneered by Intel Corporation in the 1980s to enable semiconductor manufacturers to ramp up production of microchips quickly.

There are countless vacuum chamber builds available and, if you partner with VACGEN, you can benefit from a bespoke project that’s tailored to your exact needs – no matter how advanced the application.