Introduction

A Nickel-Iron Alloy is a type of magnetic shielding material that is often used in electron spectroscopy chambers to minimise external magnetic interference. Electron spectroscopy techniques, such as X-ray photoelectron spectroscopy (XPS) or Auger electron spectroscopy (AES), are highly sensitive to magnetic fields. External magnetic fields can distort the trajectories of electrons, leading to inaccuracies in the measurements and affecting the overall performance of the spectroscopy system.

Physical Properties

Nickel-Iron Alloy's can be used as a very effective magnetic screen as it exhibits high attenuation at low levels of the interference field (e.g., earth’s magnetic field). There are certain design criteria which relate both to the physical properties of the alloy and the way that the chamber must be constructed. These must be considered before embarking on a chamber design using this alloy. For instance, dished ends or hemispheres should always be used, as opposed to flat base and top plates as this will reduce the need for extra thick material and therefore reduce the overall mass.

Low Magnetic Field

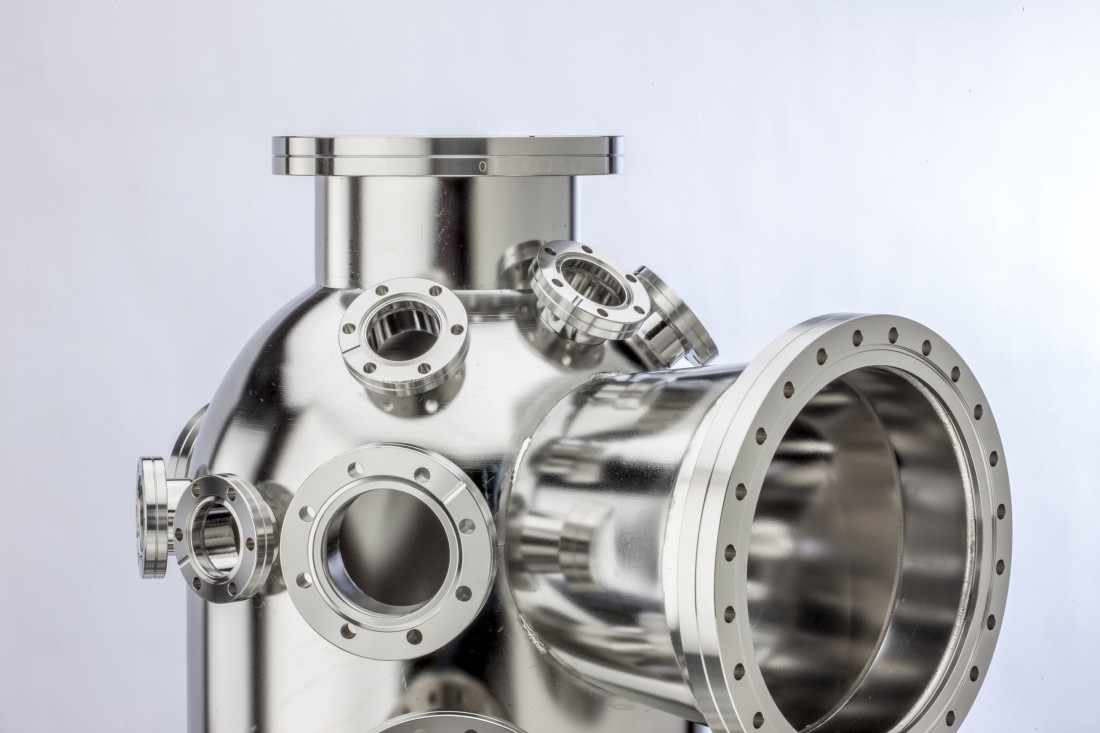

Nickel-Iron vessels provide an internal volume with low residual magnetic field (typically <5 milligauss) and are desirable on experimental systems involving low energy electrons (<100eV). These experiments require chambers with many ports accommodating the detectors and electron sources. A hole made in the alloy envelope reduces the shielding effectiveness. The penetration by the external field extends internally to a distance approximately equal to the hole diameter. The solution is to provide a port made from the alloy on the vacuum vessel with a length at least equal to its diameter. Bell-jar type chambers must be fitted with a perforated Nickel-Iron baseplate to allow for pumping and to provide access for drives, feedthroughs etc. There must be substantial Nickel-Iron Alloy overlap between the baseplate and the chamber walls, and the Nickel-Iron/Nickel-Iron contact should be as tight as possible to form a complete magnetic circuit.

Magnetic Shielding

Nickel-iron alloy has high magnetic permeability, which means it can effectively redirect and absorb magnetic flux. By using Nickel-Iron in the construction of electron spectroscopy chambers, the aim is to create a magnetic shield that reduces the influence of external magnetic fields on the sensitive electron trajectories within the chamber. The low magnetic permeability of the alloy helps prevent the penetration of external magnetic fields, providing a controlled and stable environment for electron spectroscopy experiments. This is crucial for obtaining accurate and reliable data in these types of experiments where precise measurements are essential.

Summary

In summary, Nickel-Iron Alloy's are used in electron spectroscopy chambers to minimise external magnetic interference and create a stable magnetic environment, ensuring the accuracy and reliability of the spectroscopic measurements. Our wealth of experience in custom vacuum projects, ensure you can trust our dedicated team to assist in the design and production of even the most bespoke chamber requirements. We have the capability to supply ultra-high vacuum chambers of any complexity, in a range of materials - including, stainless steel, aluminium, aluminium alloys and nickel-based superalloys. Throughout our partnership, experienced technical staff are on hand to manage your chamber project through manufacture, providing information and support, ensuring that the project’s build targets are met. As a result, VACGEN provide unrivalled value for money by supplying fabrications that fulfil your requirements first time, every time.

If you are looking for a chamber manufacturer who can fulfil your order, then contact us today for a quotation.