Vacuum chambers are often the central point of technical research environments where test settings need to be totally clean – even at a molecular level.

A vacuum is a low-pressure space where all matter that could affect a testing or manufacturing process has been removed. In a vacuum chamber, air and pressure is removed from a confined, metal enclosure. This creates an ultra-clean setting where the performance of applications for manufacturing and scientific processes can be examined.

For example, space and aerospace industries often use vacuum testing to re-create the atmosphere in space and measure how components respond. The benefit of vacuum chambers is their ability to simulate environmental conditions and assist industry in developing their products – all while maintaining a process that is absolutely clean.

Vacuum chambers are designed to fit the unique needs of highly progressive industries

Entirely configurable and often created to bespoke requirements, vacuum chambers help to advance engineering and manufacturing competence across numerous sectors, including:

-

… and more. |  |

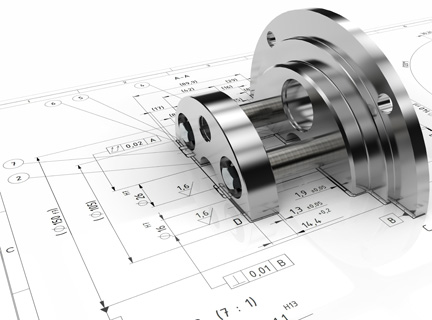

Standardised ranges of configurable chambers are made available for convenience – often in bell jar, ball, pill and cylindrical shapes. However, there are countless possibilities, and a vacuum chamber can be fabricated to suit the precise industry it services; be that a standard configurable chamber for science or a customer box chamber for deposition.

There is also the option to include additional services such as bake out and residual gas analysis respectively, this to improve the cleanliness and prove the vacuum integrity of the chamber.

VACGEN vacuum chambers offer innovative capabilities that others do not

Vacuum chambers run at different pressures and not all of these will be suitable for advanced applications.

VACGEN are proud to offer ultra-high vacuum technology, which is vital for sectors such as the semiconductor industry that demand the most enhanced levels of cleanliness and precision.

If vacuum pressure is unreliable, tests will be spoiled and require re-working. This can result in increased costs and lead times which damage the reliability and profitability of your operation; not to mention the possibility of a complete halt on manufacturing if a component is delayed to the extent that a project can’t be completed on time.

VACGEN will ensure that you can mitigate these issues with detailed inspection reports built into the process, so you can plan ahead and test with confidence. This includes leak detection and proven vacuum tightness, so you can guarantee and demonstrate that the right specifications are met at every stage.

Collaborative vacuum chamber design will broaden the possibilities of your testing and strengthen its output

At VACGEN, we design far more than the basic range of vacuum chambers. If you have a design concept but aren’t sure that it’s manufacturable, we have the experience to turn those complex ideas into practical builds – so you can meet the unique demands of your process, without compromise.

Complete assembly solutions as standard

We have over 100 years of combined experience in the supply of ultra-high vacuum chambers manufactured to specific requirements. Every customer is assigned a project engineer who will oversee your build from design, through engineering and completion, to delivery.

Our manufacturing capabilities include:

-

… and much more. |  |

No matter how unique the requirement, we can provide the end-to-end solution that furthers the capability of your process.

Do you have a project that you’d like to discuss? Our expert team is ready to help.