Abstract:

This document looks at vacuum technology and its many applications across several industrial sectors, including semiconductors, scientific instrument manufacturing, research, energy, defence, aerospace, and medical. Essentially vacuum technology is indispensable for achieving controlled environments which in turn are crucial for the precision required in today's technology. VACGEN emerges as a leading innovator in this specialised area, providing tailored vacuum motion solutions for each sector's unique demands. This comprehensive guide discusses the specific needs of each sector and highlights how VACGEN's expertise can enable businesses to succeed in this almost incredible branch of technology.

Table of Contents

Introduction

1.1 Vacuum Technology: The Backbone of Modern Industry

1.2 VACGEN: Pioneers in Vacuum Motion Solutions

Vacuum Technology Essentials

2.1 Understanding the Vacuum Environment

2.2 Vacuum Chambers: The Heart of the System

2.3 Essential Components and Accessories

Semiconductors

3.1 Vacuum in Semiconductor Manufacturing

3.2 Vacuum's Role in Wafer Production

3.3 VACGEN's Impact on Semiconductor Manufacturing

Scientific Instrument Manufacturing

4.1 The Role of Vacuum in Precision Instruments

4.2 The Role of Vacuum in Research

4.3 Customised Solutions for Scientific Instrumentation

Research

5.1 Vacuum in Experimental Research

5.2 Accelerators and Synchrotrons: Vacuum's Contribution

5.3 VACGEN's Part in Cutting-edge Research

Energy

6.1 Vacuum Applications in Energy Production

6.2 Fusion and Vacuum Technology

6.3 VACGEN's Contribution to the Energy Sector

Defence

7.1 Vacuum Technology in Defence

7.2 Military Electronics and Vacuum

7.3 VACGEN's Role in Defence Applications

Aerospace

8.1 Vacuum's Role in Space Exploration

8.2 Space Simulation and Vacuum Chambers

8.3 VACGEN's Support for Aerospace Innovation

Medical

9.1 Vacuum's Role in Medical Devices

9.2 MRI Machines and Vacuum Technology

9.3 VACGEN's Contribution to Medical Advancements

Selecting the Best Vacuum Motion Solutions

10.1 Identifying Your Specific Needs

10.2 Tailoring Solutions with VACGEN

10.3 Factors to Consider in Solution Selection

10.4 Future-Proofing with VACGEN

Conclusion

11.1 The Crucial Role of Vacuum Motion Solutions

11.2 Partnering with VACGEN for a Brighter Future

References

Introduction

1.1 Vacuum Technology: The Backbone of Modern Industry

Vacuum technology plays a vital role in today's industry. It comes into its own in sectors such as semiconductors, scientific instrument manufacturing, research, energy, defence, aerospace, and medical. On a simplistic level, vacuum technology involves creating and maintaining an environment with reduced pressure levels, often well below atmospheric conditions. This carefully controlled environment provides a platform for various industrial processes, experiments, and manufacturing activity which are just not possible at normal atmospheric pressure.

There are many applications, encompassing both fundamental scientific research and industrial production. From the manufacture of semiconductors to the development of cutting-edge medical devices, vacuum technology is a driver behind invention and progress. However, not all vacuum solutions are created equal, and the unique needs of each industry sector demand specially tailored vacuum motion solutions.

1.2 VACGEN: Pioneers in Vacuum Motion Solutions

With a reputation for excellence spanning decades, VACGEN is at the forefront of the design and manufacture of customised vacuum motion solutions for a range of industrial sectors. VACGEN's commitment to providing the best solutions and customer satisfaction has made it a trusted partner for industries seeking the latest in vacuum technology. This guide aims to explain the essential components of vacuum systems, discuss the specific needs of each sector, and highlight how VACGEN's expertise and customisable solutions empowers industry to push the boundaries of technological advancement.

Vacuum Technology Essentials

2.1 Understanding the Vacuum Environment

Before discussing the applications of vacuum, let's define the terms. A vacuum is a space devoid of matter, or more precisely, a space with pressure lower than that of the Earth's atmosphere. The measurement of vacuum is typically expressed in pressure units such as torr, millibar, or pascal, with lower values indicating higher degrees of vacuum.

Understanding the level of vacuum is most important as different applications require specific conditions. For example, high-vacuum environments, characterised by extremely low pressures, are essential for semiconductor manufacturing and certain research experiments. Rough vacuum, with higher pressures but still lower than atmospheric pressure, is suitable for applications like vacuum drying and some medical processes.

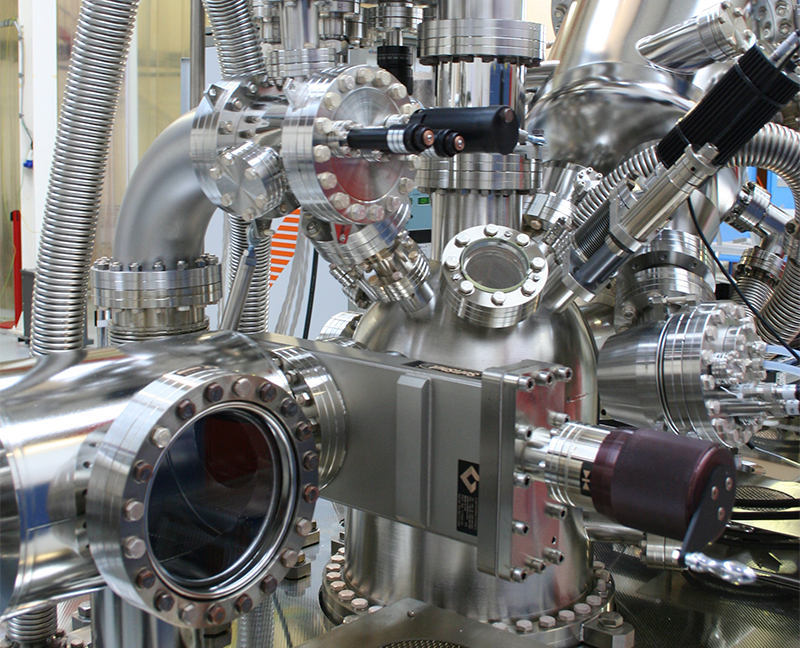

2.2 Vacuum Chambers: The Heart of the System

Vacuum chambers can vary in size and complexity, from small chambers used in laboratories to large industrial-scale chambers. These chambers are commonly used in various scientific, industrial, and manufacturing applications. The primary purpose of a vacuum chamber is to manipulate the pressure and environment within it for specific purposes. They often include features such as pumps to create and maintain the vacuum, gauges to monitor pressure, and various ports for introducing or extracting materials or samples.

Different types of vacuum pumps are used to establish and maintain the vacuum inside the chamber, including rotary vane pumps, turbomolecular pumps, and diffusion pumps, depending on the required vacuum level and application. The choice of pump and vacuum level depends on the specific needs of the experiment or process being conducted within the chamber.

Rotary Vane Pumps: These pumps are widely used in rough and medium vacuum applications. They operate by trapping gas in a rotating vane mechanism and then exhausting it.

Roots Blowers: Roots blowers are often used in combination with other pumps to increase pumping speed in high-flow-rate applications.

Diffusion Pumps: These pumps are used in high-vacuum applications and rely on vapour jets to remove gas molecules.

Turbo Molecular Pumps: Turbos are ideal for achieving ultra-high vacuum levels and operate by using high-speed rotating blades to transfer gas molecules to the pump's exhaust.

Cryogenic Pumps: Cryopumps use very low temperature to capture and condense gas molecules, making them suitable for ultra-high vacuum applications.

Choosing the right pump is crucial to achieving the required vacuum levels for specific applications. The choice of pump type depends on pumping speed, gas composition, and the presence of contaminants.

2.3 Essential Components and Accessories

In addition to vacuum pumps, a vacuum system will consist of several essential components and accessories, each designed to meet specific requirements. These can include:

Valves: These play a critical role in controlling the flow of gas in and out of the vacuum system. They can be manual or automatic depending on the application.

Pressure Gauges: These instruments are used to monitor and measure vacuum levels within the system.

Vacuum Seals: Seals prevent leaks and maintain the integrity of the vacuum environment. They are made to withstand high vacuum pressure and temperature variation.

Feedthroughs: Feedthroughs allow the passage of electrical, mechanical, or fluid connections into the vacuum chamber while maintaining the vacuum integrity.

Vacuum Instruments: Instruments like sample manipulators, rotary drives, linear drives, and transfer devices are used to move samples or substrates around the vacuum system and perform in-vacuum tasks.

Understanding these components and their roles is essential for configuring a vacuum system that meets the specific needs of an application. Here are a some of the ways in which vacuum is used across the various sectors.

Semiconductors

3.1 Vacuum in Semiconductor Manufacturing

The semiconductor industry is synonymous with precision, miniaturisation, and technological advancement. The production of integrated circuits (ICs), microchips, and electronic components requires an ultra-clean and controlled manufacturing environment. Vacuum technology plays a critical role in semiconductor manufacturing by enabling processes that demand high purity, precise control, and contamination-free conditions.

Key applications of vacuum technology in semiconductor manufacturing include:

Chemical Vapour Deposition (CVD): In CVD processes, thin films of material are deposited onto semiconductor wafers. Vacuum conditions are necessary to eliminate contaminants and ensure uniform film deposition. CVD systems use electromechanical components like gas flow controllers, valves, and temperature control systems to deposit thin films of materials onto wafers.

Physical Vapour Deposition (PVD): PVD techniques involve the deposition of material by physical means, such as sputtering or evaporation. High vacuum is essential to maintain the purity of deposited materials. PVD tools utilise electromechanical components such as sputtering targets, magnetrons and shutter mechanisms to deposit thin films on a substrate.

Ion Implantation: Ion implantation is used to introduce dopants into semiconductor materials. Vacuum environments prevent contamination and allow precise control over ion energies. Ion implantation tools use complex electromechanical systems to generate and accelerate ions and precisely implant them into semiconductor substrates.

Wafer Inspection and Packaging: The inspection and packaging of semiconductor wafers require vacuum conditions to prevent dust, particles, and contaminants from affecting the final product. Machines for inspecting and measuring semiconductor wafers often contain precision stages and optical systems for accurate measurements.

3.2 Vacuum's Role in Wafer Production

One of the critical steps in semiconductor manufacturing is the production of silicon wafers. These wafers serve as the substrate for the creation of microchips and ICs. To achieve the required levels of purity and precision, vacuum technology is employed in various stages of wafer production:

Wafer Processing Equipment: These instruments are used in various stages of semiconductor fabrication, including deposition, etching, photolithography, and chemical-mechanical planarisation.

Metrology and Inspection Tools: These instruments are designed for measuring and inspecting semiconductor wafers to ensure quality and accuracy.

Testing and Characterisation Equipment: These instruments are used to test and evaluate the electrical and physical properties of semiconductor devices.

Packaging and Assembly Equipment: These instruments are used in the packaging and assembly of semiconductor components into final products.

VACGEN's Contribution to Semiconductor Manufacturing:

VACGEN's expertise in vacuum motion solutions has proved indispensable in semiconductor manufacturing. Their vacuum components and systems are designed to meet all critical requirements of the semiconductor industry. By offering customised solutions for wafer production, VACGEN plays a crucial role in driving the industry forward with innovative solutions for a new era of tech.

Scientific Instrument Manufacturing

4.1 The Role of Vacuum in Precision Instruments

Microscopically accurate instruments are essential tools for researchers and scientists across all industry sectors. These instruments require precision, stability, and the ability to operate in controlled environments. Vacuum technology is integral to the manufacturing of scientific instruments, as it provides the necessary conditions for highly accurate measurement and experimentation.

Scientific instruments that benefit from vacuum technology include:

Mass Spectrometers: These analyse the make-up of substances by measuring the mass-to-charge ratio of ions. Vacuum is essential to maintain the integrity of the ion beam and reduce interaction with air molecules.

Electron Microscopes: Electron microscopes use electron beams to achieve high-resolution imaging. Operating in a vacuum chamber eliminates air molecules that can scatter electrons. Electron microscopes operate at very high resolutions, often at the nanoscale or even atomic scale. Sample manipulators provide the fine control required to achieve accurate positioning and imaging of specimens at these scales.

Scanning Tunnelling Microscopes (STMs): STMs are used for imaging surfaces at the atomic level. Vacuum environments prevent contamination and interference during scanning. Electromechanical stages are crucial components of STM systems, enabling researchers to conduct experiments with atomic-level precision and control.

X-ray Spectrometers: X-ray spectrometers analyse the elemental composition of materials. Mu-metal chambers can maintain these vacuum conditions while providing magnetic shielding, ensuring that both the surface analysis and magnetic shielding requirements are met. Mu-metal chambers help ensure that the recorded XPS spectra are free from magnetic field interference, leading to more accurate and reliable data. XPS instruments often use a monochromator assembly to control the energy of the X-ray source. This assembly includes various electromechanical components, such as diffraction gratings, crystals, and mechanical drives, to select and tune the X-ray energy used for excitation. Accurate control of the X-ray energy is essential for achieving high-resolution XPS spectra.

4.2 The Role of Vacuum in Research

Research tools and instruments play a pivotal role in advancing scientific knowledge and innovation. Whether used in laboratories, universities, or research institutions, these tools must meet rigorous standards of precision and reliability. Vacuum technology enhances the performance of research tools by:

Minimising Interference: Vacuum environments reduce the presence of air molecules that can interfere with measurements, imaging, or experiments.

Enhancing Stability: Vacuum provides a stable and controlled environment, reducing the impact of temperature changes, air pressure changes, and contamination.

Increasing Sensitivity: Lowering the pressure in vacuum chambers can increase the sensitivity of instruments, allowing researchers to detect minute changes and phenomena.

4.3 Customised Solutions for Scientific Instrumentation:

Electromechanical assemblies could include lens assemblies, sample storage, heater assemblies and manipulation sub-assemblies. VACGEN's commitment to precision and innovation aligns seamlessly with the needs of scientific instrument manufacturers. They specialise in providing customised vacuum solutions that cater to the unique requirements of research tools.

Research

5.1 Vacuum in Experimental Research

Research, the pursuit of knowledge and understanding. Experimental research, in particular, relies on controlled environments to conduct investigations, tests, and experiments. Again, vacuum technology plays a pivotal role in a wide range of research fields, for example:

Material Science: Researchers use vacuum technology to study the properties of materials, investigate phase transitions, and develop new materials. This is a continual ongoing process as the vacuum technology evolves. Vacuum compatible motion assemblies consist of various components that help to manipulate the sample, control the X-Ray source and electron analyser, and maintain the necessary vacuum conditions for accurate measurements.

Astronomy and Astrophysics: Telescopes and detectors designed for space observation operate in a vacuum to eliminate atmospheric interference. Vacuum electromechanical assemblies are engineered to meet the specific requirements of the space environment or vacuum conditions, ensuring that they maintain functionality, precision, and reliability in these challenging settings.

Nuclear Fusion: Fusion research relies on vacuum chambers to create conditions conducive to nuclear fusion reactions. Vacuum motion systems in nuclear fusion research and experiments are critical for maintaining precise control and manipulation of the plasma, diagnostic equipment, and various components within the vacuum chamber.

5.2 Accelerators and Synchrotrons:

Particle accelerators and synchrotrons are powerful tools used in fundamental research to study particles and subatomic phenomena. These machines require ultra-high vacuum conditions to operate effectively. Vacuum technology is essential in these facilities for several reasons:

Particle Control: In particle accelerators, vacuum chambers guide and accelerate particles, minimising interactions with gas molecules.

Radiation Control: Synchrotrons emit intense synchrotron radiation for various experiments. Vacuum environments prevent the absorption and scattering of this radiation.

Preservation of Particle Beams: Vacuum chambers maintain the integrity of particle beams, ensuring accurate measurements and controlled collisions.

VACGEN's Support for Cutting-edge Research:

VACGEN's expertise extends to the field of research, where their vacuum solutions enable scientists to push the boundaries of knowledge. By providing vacuum chambers, specialised feedthroughs, and customised components such as synchrotron beam-line choppers, monochromator assemblies, lens assemblies and analyser instruments, VACGEN facilitates ground-breaking experiments and discoveries, tailored to the needs of research facilities.

Energy

6.1 Vacuum Applications in Energy Production

The energy sector is vital for powering modern society, and the production of energy often involves high-temperature, high-pressure, and extreme conditions. Vacuum technology finds applications in energy production and research, contributing to improved efficiency, safety, and innovation. Key areas where vacuum technology is used in the energy sector include:

Nuclear Fusion: Vacuum chambers are essential for creating the conditions required for nuclear fusion, a potentially limitless and clean source of energy.

Solar Panels: Vacuum deposition processes are used to manufacture thin-film solar panels, increasing their efficiency, and reducing production costs.

Oil Refining: Vacuum distillation is employed in the refining of crude oil to separate different hydrocarbon fractions at lower temperatures and pressures.

6.2 Fusion and Vacuum Technology

Nuclear fusion holds the promise of clean and abundant energy generation, akin to the processes that power the sun and stars. Achieving controlled nuclear fusion on Earth requires the creation of extreme conditions, including high temperature and pressure. Vacuum technology plays a pivotal role in fusion research and development:

Confinement of Plasma: Vacuum chambers are used to create a vacuum environment where plasma, the superheated state of matter required for fusion, can be safely contained, and controlled.

Reduction of Energy Loss: In vacuum, energy losses due to collisions with gas molecules are minimised, allowing plasma to reach the required temperatures for fusion.

Material Testing: Vacuum conditions are essential for testing materials that will be exposed to the extreme conditions of a fusion reactor, ensuring their integrity and safety.

VACGEN's Contribution to the Energy Sector:

VACGEN's involvement in the energy sector extends to nuclear fusion research and other energy-related applications. Their vacuum solutions enable the development of next-generation energy sources and contribute to the quest for sustainable and clean energy production.

Defence

7.1 Vacuum Technology in Defence

The defence sector demands cutting-edge technology to ensure the safety and security of nations. Vacuum technology finds applications in defence, particularly in military electronics, radar systems, aerospace, and testing facilities. The ability to create controlled environments and ensure the reliability of critical components is paramount in defence applications. Key areas where vacuum technology is employed in defence include:

Space Simulation: Vacuum chambers are used to simulate space conditions and test the performance of spacecraft and satellites.

Radar Systems: High-frequency vacuum tubes in radar systems require vacuum environments to operate effectively.

Military Electronics: Vacuum components and technology play a role in ensuring the reliability and performance of military electronics and communication systems.

7.2 Military Electronics and Vacuum

Vacuum tubes, also known as electron tubes or thermionic valves, have a long history in electronics and have been used extensively in military applications. While modern electronics have largely transitioned to solid-state devices, vacuum tubes still find use in certain high-power, high-frequency, and specialised military electronics, including:

Radar Systems: Vacuum tubes are used in radar transmitters for their ability to generate high-power, high-frequency signals reliably.

Electronic Warfare: Some electronic countermeasures and jamming systems use vacuum tubes for their robust performance in high-stress environments.

Space-Based Systems: In space-based applications, vacuum tubes are employed due to their ability to withstand the harsh conditions of space.

VACGEN's Role in Defence Applications:

VACGEN's vacuum solutions are tailored to meet the stringent requirements of defence applications. Whether it's providing vacuum chambers for space simulation or custom vacuum components for military electronics, VACGEN supports the defence sector in achieving reliability and performance in critical systems.

Aerospace

8.1 Vacuum's Role in Space Exploration

The aerospace industry is synonymous with exploration, innovation, and pushing the boundaries of human knowledge. Space exploration, in particular, relies heavily on vacuum technology. The extreme conditions of space, including vacuum, high radiation, and temperature variations, necessitate advanced technology and precision engineering. Key applications of vacuum technology in aerospace include:

Space Simulation: Vacuum chambers are used to simulate the conditions of outer space, allowing spacecraft and components to be tested for reliability.

Rocket Propulsion: Vacuum conditions are crucial in the testing and development of rocket engines and propulsion systems.

Space Telescopes: Space telescopes like the Hubble Space Telescope operate in the vacuum of space to capture high-resolution images of deep space objects. These rely on vacuum-compatible electromechanical assemblies for various components, including mirror positioning and fine-tuning mechanisms. In the vacuum of space, such assemblies must maintain their functionality without the aid of an atmosphere.

Spacecraft Instruments: Instruments and detectors on space probes, rovers, and landers often operate in vacuum environments. Vacuum-compatible electromechanical assemblies are used for moving parts, including sample collection systems, robotic arms, and drilling mechanisms.

8.2 Space Simulation and Vacuum Chambers

Space simulation chambers are vital tools in aerospace research and development. These chambers create vacuum environments that mimic the conditions of space, allowing engineers and scientists to test and validate spacecraft, components, and instruments under realistic conditions. The key roles of vacuum chambers in aerospace include:

Thermal Testing: Vacuum chambers are used to subject spacecraft and components to extreme temperature variations, replicating the temperature extremes encountered in space.

Vibration Testing: Simulating the vibrations experienced during launch and space travel helps ensure the structural integrity of spacecraft and payloads.

Radiation Testing: Space simulation chambers can recreate the high levels of radiation present in space, allowing for the assessment of electronics' performance and durability.

VACGEN's Support for Aerospace Innovations:

As pioneers in vacuum motion solutions, VACGEN has a significant impact on aerospace research and development. Their vacuum chambers and customised solutions contribute to the success of space missions and the advancement of aerospace technology, enabling exploration of new frontiers.

Medical

9.1 Vacuum in Medical Devices

The medical industry is constantly evolving, with a focus on improving patient care, diagnostics, and treatment. Vacuum technology plays a vital role in various medical applications, contributing to advancements in diagnostics, imaging, and therapeutic devices. The medical sector benefits from vacuum technology in several ways:

MRI Machines: Magnetic Resonance Imaging (MRI) machines use powerful magnets and vacuum environments to produce high-resolution images of internal body structures.

Analytical Instruments: Vacuum is used in analytical instruments such as mass spectrometers and electron microscopes for medical research and diagnostics.

Dental Devices: Vacuum technology is employed in dental equipment, including dental chairs and suction systems, to maintain surgically clean environments.

9.2 MRI Machines and Vacuum Technology

Magnetic Resonance Imaging (MRI) is a cornerstone of modern medical diagnosis, providing non-invasive, high-quality images of the body's internal structures. The operation of MRI machines relies on superconducting magnets and the use of vacuum technology:

Superconducting Magnets: MRI machines use superconducting magnets, which require extremely low temperatures to function efficiently. Vacuum insulation is employed to maintain these low temperatures, reducing energy consumption and heat dissipation.

RF Coils and Vacuum: RF coils used in MRI machines generate radiofrequency pulses and receive signals from the patient's body. These coils operate within a vacuum environment to reduce electromagnetic interference and improve signal quality.

VACGEN's Contribution to Medical Advancements:

VACGEN's expertise in vacuum technology extends to the medical field, where their solutions contribute to the development and operation of advanced medical devices. Vacuum autoclaves, all-metal medical valves and plasma surface treatment systems are just a few examples of how VACGEN has contributed to the medical industry. By ensuring the reliability and performance of vacuum systems in medical applications, VACGEN plays a role in improving patient care and diagnostics.

Selecting the Best Vacuum Motion Solutions

10.1 Identifying Your Specific Needs

Selecting the best vacuum motion solutions for your needs requires a thorough understanding of your application's requirements and challenges. Here are the key steps to consider:

Define Your Objectives: Clearly define the goals and objectives of your project. What is the desired vacuum level? Are there specific temperature or pressure requirements? What are the performance expectations?

Consider Environmental Factors: Evaluate the environmental conditions in which the vacuum system will operate. Will it be exposed to harsh chemicals, extreme temperatures, or radiation? Understanding these factors is crucial for selecting suitable materials and components.

Assess Contamination Risks: Contamination can impact the quality and reliability of vacuum systems. Identify potential sources of contamination and develop strategies to mitigate them.

Determine Size and Configuration: Determine the required size and configuration of the vacuum chamber, electromechanical assemblies, or system. Consider factors such as available space, component placement, and accessibility for maintenance.

Budget and Timeline: Establish a budget for your project and define the timeline for implementation. Ensure that your budget aligns with the desired performance and quality of the vacuum system.

10.2 Tailoring Solutions with VACGEN

VACGEN's expertise lies in crafting customised vacuum motion solutions that align with the specific needs of your sector. Here's how VACGEN can assist in tailoring solutions to meet your requirements:

Consultation and Design: VACGEN's team of experts will work closely with you to understand your project's goals and challenges. They will then design a customised solution.

Custom Components: VACGEN specialises in manufacturing custom vacuum components, including sample manipulators, electromechanical assemblies, and vacuum chambers. These components are engineered to match the unique specifications of your project.

Quality and Reliability: VACGEN places a strong emphasis on quality and reliability. Their solutions are designed to operate consistently under demanding conditions, ensuring long-term performance and minimal downtime.

Technical Support: VACGEN offers comprehensive technical support to assist you during installation, operation, and maintenance. Their team is readily available to address any questions or issues that may arise.

10.3 Factors to Consider in Solution Selection

When selecting vacuum motion solutions, there are several critical factors to consider:

Vacuum Level: The required vacuum level depends on your application. Ensure that the chosen vacuum system can achieve and maintain the necessary pressure conditions and the components are vacuum compatible.

Materials and Compatibility: Evaluate the compatibility of materials with the process or application. Consider factors such as chemical resistance, thermal stability, and radiation tolerance.

Pumping Speed: The pumping speed of the vacuum system should match the gas load and evacuation requirements of your process. Oversized or undersized pumps can lead to inefficient operation.

Contamination Control: Implement measures to prevent contamination, such as using suitable materials, filtration, and cleanroom practices.

Safety and Compliance: Ensure the system complies with safety regulations and industry standards applicable to your sector.

Cost of Ownership: Consider the total cost of ownership, including initial investment, operational costs, and maintenance expenses.

10.4 Futureproofing with VACGEN

In a changing technological landscape, future-proofing your vacuum motion solutions is essential. VACGEN's commitment to innovation ensures their solutions are designed to adapt and evolve with changing industry demands. By partnering with VACGEN, you can benefit from:

Advanced Technology: VACGEN continually invests in research and development to incorporate the latest advancements in vacuum technology.

Flexibility and Scalability: VACGEN's custom solutions are designed with flexibility and scalability in mind, allowing you to adapt to changing requirements and expand your capabilities.

Long-Term Support: VACGEN provides ongoing support and maintenance services to extend the lifespan of your vacuum systems and ensure consistent performance.

Collaboration: VACGEN collaborates with clients to anticipate future needs and develop solutions that align with emerging trends and technologies in their respective industries.

Conclusion

11.1 The Crucial Role of Vacuum Motion Solutions

Vacuum technology is a foundation of precision, innovation, and reliability in various industrial sectors, including semiconductors, scientific instrument manufacturing, research, energy, defence, aerospace, and medical. The controlled environments created by vacuum technology are essential for achieving precise measurements, conducting experiments, and manufacturing advanced products.

Within this dynamic landscape, VACGEN stands as a trusted partner and pioneer in the field of vacuum motion solutions. Their expertise, commitment to quality, and dedication to customisation empower industries to overcome challenges and excel in a competitive global market.

11.2 Partnering with VACGEN for a Brighter Future

In an era of rapid technological advancement, selecting the best vacuum motion solution is vital to your success. VACGEN's commitment to innovation and customer satisfaction makes them the ideal partner for industries seeking tailored vacuum solutions that meet and exceed their specific needs.

References

[1] "Vacuum Technology in High-Tech Industries," John Wiley & Sons, 2015.

[2] "Vacuum Science and Technology," CRC Press, 2016.

[3] "Semiconductor Manufacturing Technology," World Scientific Publishing, 2017.

[4] "Handbook of Vacuum Technology," John Wiley & Sons, 2016.

[5] "Vacuum Technology and Applications," Elsevier, 2016.

[6] "Introduction to Vacuum Science and Technology," Oxford University Press, 2017.