Introduction

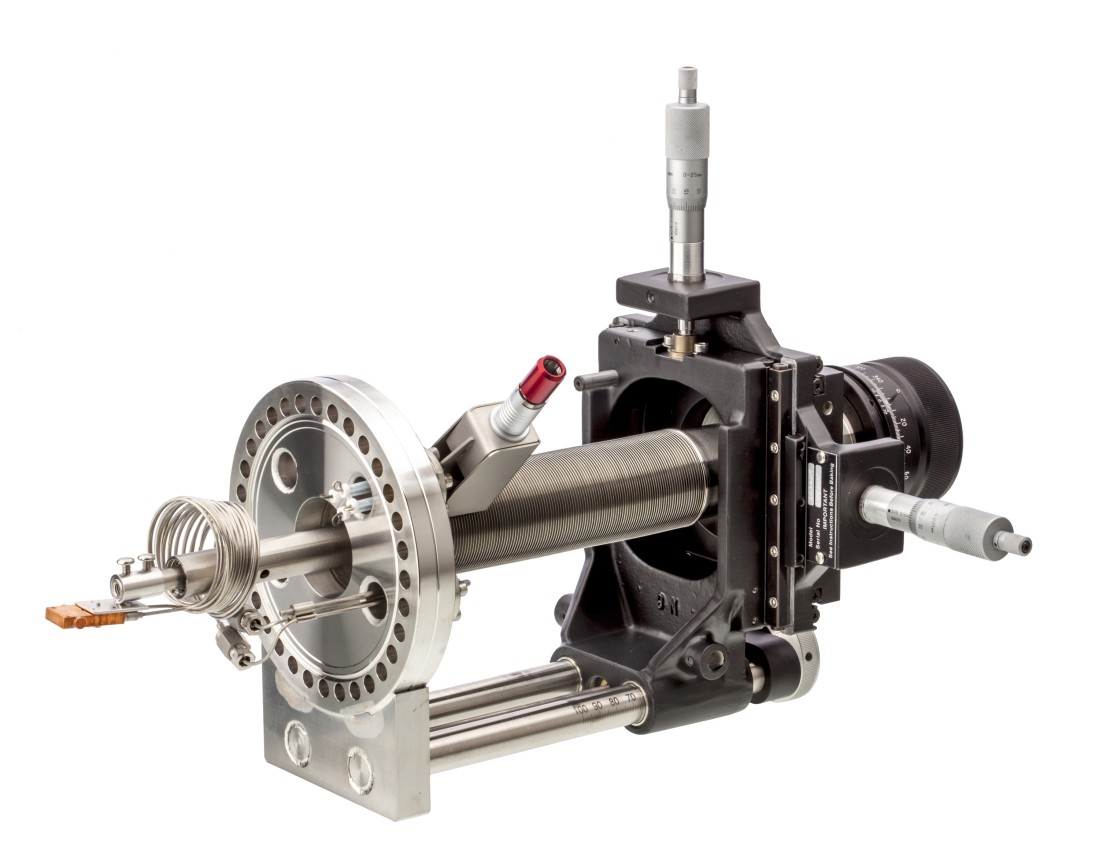

Material science is a crossover of disciplines having roots in Physics, Chemistry and Engineering. Covering all three, UHV Manipulation is becoming ever more important in ensuring micro-precision in both surface analysis and deposition.

Surface Analysis

Movement and Mapping

By moving a sample along the x, y, and z-axis, manipulators lead the way in creating detailed elemental maps. For example, in material research, this three-way mobility helps scientists find and fix minute defects or impurities. When dealing with atomic measurements, even the tiniest imperfection can alter a material's electrical conductivity.

Temperature Variability

By heating or cooling samples, manipulators enable the study of phase transitions. For example, understanding the temperature at which a material loses electrical resistance can lead to solutions surrounding energy storage, automotive and optics.

Orientation

Manipulators can be mounted in multiple orientations to accommodate the scientific experimental requirements. As a general guidance sample surfaces are face down for deposition, face up for lab-based surface analysis or face on for synchrotron science – however every experiment is very different, and the orientation should be considered.

Tilt

Sample tilt can be used for adjusting the escape trajectory of electrons, especially in photoelectron spectroscopy, this can lead to deeper insight within the sphere of surface analysis.

Sample Bias

In nanotechnology, applying a bias helps in tunnelling microscopy or photoemission. By adjusting the energy of emitted photoelectrons, scientists can model atomic landscapes, essential in the design of nano-scale devices.

Customisation with VACGEN

In sectors such as biotechnology, where surfaces might be more delicate or even organic, VACGEN's manipulators can be tailored to your requirements.

Deposition

Temperature Control

In the growing field of thin-film technology, temperature-sensitive deposition is crucial. Manipulators that have the capability to cope with high and low temperatures are essential tools in the development of, for example, solar cells to advanced computer memory devices.

Uniformity

For Original Equipment Manufacturers, uniform deposition can affect efficiency and lifespan of components. For example, uneven layers in microprocessors can lead to overheating or short-circuits which can affect entire networks. More consistency means more longevity and reliability.

Substrate Rotation

In optical research, where the precision of lens coatings can influence clarity and focus, substrate rotation manipulators make sure of an even application. This is vital for instruments such as telescopes, where even a minute aberration can lead to significant distortion.

Versatility with VACGEN

From aerospace to automotive industries, different materials require different deposition environments. VACGEN's manipulators cater to a spectrum of needs. VACGEN makes sure these materials are prepared treated and manipulated to the highest precision possible.

In Conclusion

UHV sample manipulation is not just physics and engineering—it’s a vital step in scientific discovery and innovation. Whether it’s improving the efficiency of a solar cell or designing the next generation of computer chips, the role of precise manipulation under UHV conditions remains hugely influential in advancing scientific knowledge.

Contact our sales team today to discuss your next groundbreaking development in the world of UHV.